CPU Manufacturers in Maharashtra

Your Trusted CPU Manufacturers in Maharashtra

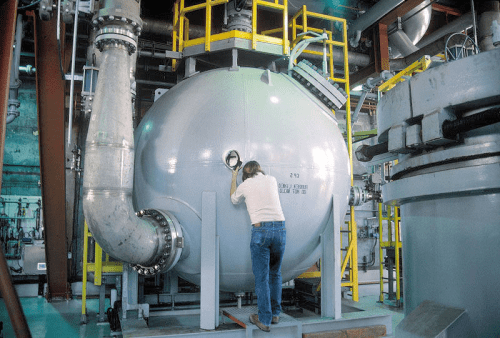

Larco India Pvt. Ltd., A leading CPU Manufacturers in Maharashtra, has established a unique benchmark for excellence as technological and industrial breakthroughs continue to grow in Maharashtra. Larco India’s products are affordable and have a focus on quality, innovation, and customer happiness.

What is a condensate polishing unit?

The condensate water that is collected from steam turbines and returned to the boiler system for reuse is cleaned using a Condensate Polishing Unit (CPU), a specialized piece of water treatment equipment used in power plants and industrial facilities. A CPU’s main function is to purge pollutants, dissolved particles, and impurities from condensate water to ensure high-quality feedwater for the boiler system and other steam-related machinery. As a result, the total steam cycle and power generation process remain effective and durable. Larco India is the Best CPU Manufacturers in Maharashtra, and also a supplier of CPU equipment.

How a Condensate Polishing Unit typically works:

- Collection of Condensate: The sentence has been rewritten in active voice to emphasise the action of steam turbines generating steam. This condensed water is referred to as condensate, and it includes a number of contaminants that accumulate during the steam cycle.

- Pre-Treatment: The condensate may undergo preliminary pre-treatment procedures, such as filtering and dearation, to remove larger particulates and gases before entering the condensate polishing unit.

- Ion Exchange Resins: Ion exchange resins are used in a condensate polishing unit during a procedure similar to that in a dealkalization unit. Specific functional groups in these resins draw and exchange ions found in the condensate water.

- Cation Exchange: Typically, cation exchange resins are used as ion exchange resins in CPUs. They trade hydrogen ions for cations, or positively charged ions. This procedure aids in the removal of cations, including sodium, calcium, and magnesium, that may cause scale formation and boiler system corrosion.

- Anion Exchange: Some CPU setups might also include anion exchange resins to remove anions (negatively charged ions) like chloride, sulphate, and bicarbonate. This further ensures that the feedwater remains free from impurities that could negatively impact the boiler and steam cycle.

- Polishing Filter: After the ion exchange process, the water might pass through a polishing filter. This filter helps capture any remaining particulates or contaminants that were not removed by the ion exchange resins.

- Degassing: Depending on the specific requirements, the CPU might include a degassing step to remove dissolved gases like oxygen and carbon dioxide. These gases can cause corrosion in the boiler and steam cycle components.

- Quality Control: The water’s quality is kept under observation throughout the CPU procedure to guarantee that it satisfies the requirements for boiler feedwater. Conductivity, pH, and purity are a few examples of the parameters that analytical instruments and sensors are used to test.

- Return to the Boiler: The condensate is reintroduced to the boiler system as high-quality feedwater after being polished and cleaned by the CPU. This promotes effective steam production and guards against corrosion and scale development in the boiler.

By supplying clean and purified water to the boiler system, Condensate Polishing Units play a crucial role in preserving the effectiveness, dependability, and longevity of power production equipment.

Applications of CPU

- Power Generation Plants: CPUs are extensively used in power plants, particularly those that use steam turbines. These systems make sure that the condensate water obtained from the turbine is fully cleaned before being transferred back to the boiler. High-quality feedwater lowers the possibility of corrosion, scale accumulation, and equipment damage, resulting in effective power generation and a prolonged equipment lifespan.

- Industrial Boilers: Businesses that use boilers for energy generation, sterilization, and other purposes benefit from CPUs. By preventing contamination, CPUs keep the condensate water clean and maintain perfect conditions inside the boiler system. Maintenance costs are lowered as a result, and energy effectiveness is raised.

- Refineries and Petrochemical Plants: For many of their processes, petrochemical and refinery facilities need a lot of steam. CPUs make sure that the water used in these processes is free of pollutants that can jeopardise the quality of the equipment and the final product.

- Paper and Pulp Industry: Steam is used in the paper and pulp industries for drying and processing. CPUs assist in preserving the feedwater’s quality by reducing corrosion and scale buildup in the papermaking machinery.

- Food and Beverage Industry: Industries that make food and beverages use steam for many procedures, including sterilization and cooking. CPUs help to guarantee the high purity of the steam utilised in these procedures, preventing contamination of products and equipment.

- Pharmaceutical Industry: Maintaining water quality is crucial for pharmaceutical manufacturing to guarantee product purity. For tasks like sterilization and cleaning, CPUs are necessary for producing steady, clean steam.

- Textile Industry: In the pharmaceutical production sector, maintaining water quality is crucial for ensuring product integrity. CPUs are necessary for producing dependable, clean steam for processes like cleaning and disinfection.

- Chemical Industry: Steam is frequently needed for high-temperature reactions that occur during chemical manufacture. CPUs make sure that the steam utilized in these operations is clean and prevents contamination of the equipment from occurring.

- Hospitals and Healthcare Facilities: Steam is used in hospitals for medical sterilization and other procedures. CPUs make sure that the steam used medical facilities is highly pure and adheres to strict safety and hygiene regulations.

- District Heating Systems: In order to heat homes and businesses, district heating systems provide steam or hot water. By guaranteeing clean feedwater, CPUs assist in maintaining the effectiveness and dependability of these systems.

- Cogeneration Plants: Cogeneration, sometimes referred to as combined heat and power (CHP), involves producing both heat and electricity at the same time. The efficiency and dependability of such plants depend heavily on CPUs.

- Desalination Plants: CPUs aid in the desalination process by ensuring the purity of the water utilised in steam-based procedures, which helps produce clean drinking water.

Condensate Polishing Units are essential in all of these applications for preserving water purity, maximising equipment performance, and boosting overall effectiveness and dependability.

Advantages of CPU

Utilizing Condensate Polishing Units (CPUs) manufactured by reputable CPU Manufacturers in Maharashtra and procured from trusted CPU Suppliers in Maharashtra brings forth a range of advantageous outcomes. Here’s an exploration of the key benefits associated with these essential systems:

- Prolonged Equipment Lifespan: Collaboration with established CPU Manufacturers in Maharashtra and reliable CPU Suppliers in Maharashtra ensures the deployment of high-quality CPUs. These units effectively remove impurities from condensate water, safeguarding equipment against corrosion and scale. As a result, the lifespan of critical machinery is extended, reducing the need for frequent replacements.

- Enhanced Operational Efficiency: CPU Manufacturers in Maharashtra, alongside dedicated CPU Suppliers in Maharashtra, offer cutting-edge technology that optimizes the efficiency of CPUs. By maintaining the purity of condensate water, CPUs enhance heat transfer efficiency. This translates to energy savings, reduced operational costs, and heightened process performance.

- Mitigated Downtime Risks: By mitigating corrosion and scale-related risks, CPUs become integral in minimizing downtime. Trusted CPU Manufacturers in Maharashtra and responsive CPU Suppliers in Maharashtra contribute to consistent system performance, ensuring uninterrupted operations and bolstering productivity.

- Economical Savings: Collaborations with reputable Maharashtrian CPU manufacturers and reasonably priced Maharashtrian CPU suppliers result in significant long-term savings. Significant cost savings are produced as a result of less energy use, fewer maintenance requirements, and the avoidance of expensive equipment failures.

- Environmental Responsibility: CPUs’ importance grows as environmental concerns develop in popularity. Industries employ water-efficient solutions that are in line with sustainability goals and environmental requirements by collaborating with responsible CPU Manufacturers in Maharashtra and eco-conscious CPU Suppliers in Maharashtra.

- Tailored Solutions: Custom CPU solutions are produced through partnerships with capable Maharashtrian CPU vendors and manufacturers. These solutions have been methodically developed to solve the distinct water quality issues that various sectors face, ensuring optimal performance and efficacy.

- Guaranteed Product Quality: Pharmaceuticals, food and beverage, and healthcare industries all depend on high-quality water for their operations. CPUs provide the creation of clean steam, maintaining the consistency and quality of final goods.

- Regulatory Compliance: Collaboration with aligned Maharashtrian CPU Suppliers and compliant Maharashtrian CPU Manufacturers ensures adherence to strict water quality laws. Industries can prevent potential compliance problems and related fines by using CPUs that adhere to regulatory standards.

- Technical Expertise: Access to specialised technical know-how is made possible by collaboration with knowledgeable Maharashtrian CPU Manufacturers and resourceful Maharashtrian CPU Suppliers. Their extensive industry expertise enables them to suggest and put into practise the CPU solutions that are most suited to the individual requirements of each application.

- Enhanced Industry Reputation: The reputation of industries is elevated by partnering with respected CPU Manufacturers in Maharashtra and renowned CPU Suppliers in Maharashtra. Establishing a dedication to efficiency, sustainability, and operational excellence builds brand reputation and encourages customer trust.

In conclusion, incorporating CPUs from reputable Maharashtra CPU Suppliers and Maharashtra CPU Manufacturers has significant advantages. These benefits highlight CPUs’ crucial position across a variety of businesses by encompassing efficiency improvement, significant cost savings, regulatory compliance, and ecological responsibility.