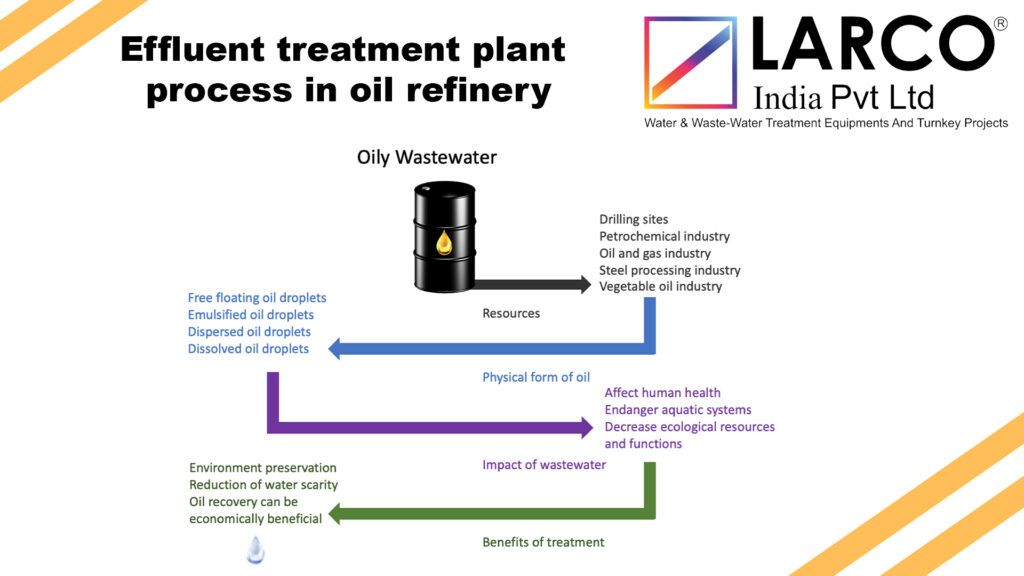

The oil refining industry has made tremendous progress in minimizing its ecological footprint with the goal of sustainable development and environmental stewardship. The use of effective effluent treatment plant (ETP) procedures is a critical component of this endeavor. In this blog, we’ll look at the significance of the Effluent treatment plant process in oil refinery, as well as its essential elements and treatment stages.

The Significance of Effluent treatment plant process in oil refinery

Industrial processes discharge effluent, which is any liquid waste discharged from industrial processes. In the context of oil refineries, wastewater frequently comprises a variety of contaminants, such as hazardous compounds, suspended particles, heavy metals, and hydrocarbons. These pollutants can pose serious risks to the environment, ecosystems, and public health if they are not appropriately addressed.

Effluent Treatment Plant Components:

Oil refineries use a variety of components called effluent treatment plants to properly treat and purify wastewater. We’ll see what are the stages of the Effluent treatment plant process in oil refinery

The key components include:

- Preliminary Treatment: Large waste, including rocks, plastic, and other solid objects, is first removed from the area via physical screening. This process makes operations run more smoothly by avoiding damage to equipment further downstream.

- Oil-Water Separation: By applying mechanical or gravity-based techniques, the oil and grease will now separate from the water. For effective oil-water separation, oil companies frequently use API separators, flotation units, or dissolved air flotation (DAF) systems.

- Biological Treatment: Biological treatment is necessary to break down the organic compounds in wastewater. A biological mechanism needs to occur to degrade the organic compounds in the wastewater. Trickling filters, aerobic and anaerobic digestion, and activated sludge processes are examples of typical biological treatment techniques.

- Chemical Treatment: To maximize the elimination of certain contaminants, chemical treatment is frequently combined with biological procedures. To aid in the collection of suspended solids and the separation of colloidal particles, chemical coagulants, and flocculants will applied. Procedures like pH modification and oxidation by chemicals used to balance acidity, get rid of heavy metals, or get rid of hazardous substances.

- Advanced Treatment Techniques: It is possible to apply cutting-edge treatment techniques like membrane filtration, reverse osmosis, or activated carbon adsorption. depending on the precise effluent characteristics and regulatory requirements. These techniques support further purification and satisfy strict discharge requirements.

Effluent Disposal and Monitoring:

Monitoring the effluent’s quality before releasing it into the environment is essential after wastewater has completed treatment. Regular testing ensures compliance with local environmental regulations while also protecting the ecosystems in the area. During wastewater monitoring, it is usual practice to analyze variables including pH, temperature, COD, BOD, total suspended solids (TSS), and heavy metal concentrations.

Conclusion:

Effluent treatment systems greatly decrease the impact of oil refineries on the environment. ETPs efficiently remove impurities using a combination of physical, biological, and chemical processes, making sure the treated effluent satisfies strict quality criteria. Oil refineries can safeguard regional ecosystems, maintain water supplies, and contribute to a cleaner, greener future by using effective and sustainable ETP processes.

Keep in mind that if sustainable growth will successfully accomplished, effective wastewater treatment practices must continually innovate and improve. Oil refineries must work to adopt the best practices available to reduce their ecological footprint and pave the way for a more sustainable sector as technology develops and environmental awareness rises. In this blog, we have shown how the effluent treatment plant process in oil refinery.